Forklift Parts Shimadzu Hydraulic SGP2 Iav Twj

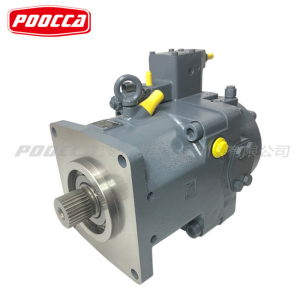

POOCCA Hydraulic, yog lub chaw tsim khoom ntawm Hydraulic iav twj, uas yog kev koom ua ke nrog R & D

1.Tus nqi sib tw heev.

2.Product Tsawg-suab nrov, high efficiency, siab compatibility, lub neej ntev.

3. Me me, muaj zog ceev ceev.

4.Excellent oil absorption zog.

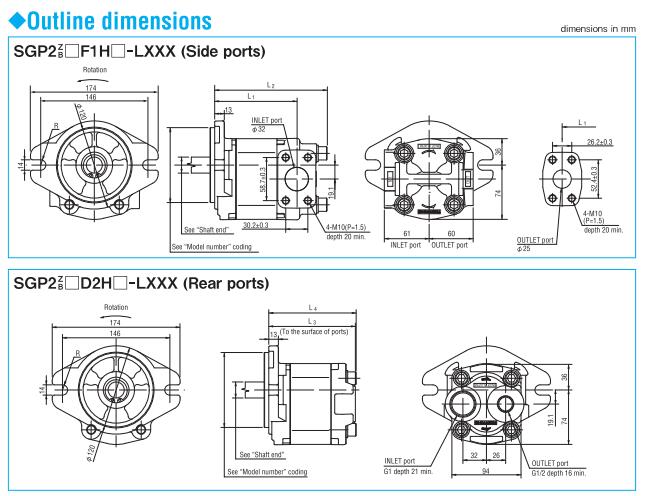

| Kev khiav tawm | Rated siab | Max. ncov siab | Ceev m-1 | Inlet siab | Pawg | ||||||||

| Series | cm3 | in3 | MPa | bar | psi | MPa | bar | psi | MIN | MAX | kg | lb | |

| 20 | 20.3 | 1.238 ib |

24.5 ib |

245 |

ib 3553 |

29.4 ib |

294 ib |

ib 4263 |

400 |

3000 |

bar -0.20-2.0

MPa 0.02-0.2 hli

psi -2.9-29 | 4.9(4.4) 1078(9.68) | |

| 23 | 23.3 | 1.421 ib | 5.1 (4.6) 11.22 (10.12) | ||||||||||

| 25 | 25.3 | 1.543 ib | 5.3 (4.8) 11.66 (10.56) | ||||||||||

| 27 | 27.4 ib | 1.671 ib | 5.4 (4.9) 11.88 (10.78) | ||||||||||

| 32 | 32.5 ib | 1.983 ib | 5.7 (5.1) 12.54 (11.22) | ||||||||||

| 36 | 36.5 ib | 2.227 ib | 3000 (2500) | 5.9 (5.3) | 12.98 (11.66) dr hab. | ||||||||

| 40 | 40.6 ib | 2477 ib | 226 | 226 | ib 3277 | 275 | 275 | ib 3988 | 2500 (2300) hli | 6.1 (5 4) | 1342 (1188) : kuv. | ||

| 44 | 44.7 ib | 2727 ib | 206 | 206 | 2987 ib | 245 | 245 | ib 3553 | 2300 (2300 hli) | 6 3 (5 6) | 1386 (1232) : kuv. | ||

| 48 | 48.7 ib | ib 2970 | 186 | 186 | 2697 ib | 226 | 226 | ib 3277 | 2300 (2000) | 6.6 (59) | 1452 (1298) hnub | ||

| 52 | 52.8 ib | 3.221 ib | 17.2 ib | 172 | 2494 ib | 20.6 | 206 | 2987 ib | 2200 (2000) | 6.8 (6.1) | 14.96 (13.42) Nws. | ||

SGP Series: SGP2-20, SGP2-26, SGP2-25, SGP2-27, SGP2-32, SGP2-36, SGP2-40, SGP2-44, SGP2-48, SGP2-52

POOCCA-Shimadzu iav twj tso kua mis yog lub twj tso kua mis sab nraud nrog cov khoom siv tsis siv neeg axial clearance them thiab radial hydraulic tshuav nyiaj li cas, uas tau txais peb lub qauv qhib. Lub tes tsho ncej yog nruab nrog lub tes tsho DU, thiab sab phaj yog ua los ntawm cov khoom siv bimetallic; Cov npog pem hauv ntej thiab nram qab yog ua los ntawm aluminium alloy tuag castings, thiab lub cev nruab nrab yog ua los ntawm cov hlau cam khwb cia, zoo txhim kho cov ntsuas kev ua tau zoo thiab kev ntseeg siab ntawm lub iav twj tso kua mis.

Khoom nta

1. Kev ua tau zoo heev, dhau ib lab kev cuam tshuam kev qaug zog nyob rau hauv cov xwm txheej ntawm 24.5MPa.

2. Kev ua haujlwm siab: Los ntawm kev tsim qauv zoo thiab ua kom zoo, cov twj tso kua mis no tau khaws cia hauv qhov ua haujlwm siab thiab ua haujlwm siab.

3. Lub neej ua haujlwm ntev: Kev hnav tsis kam tiv thaiv bearings nrog kev ua haujlwm zoo thiab kev kub siab, kev ua haujlwm siab tsis kub hnyiab.

4. Lub teeb yuag, compact thiab exquisite qauv.

5. Lub cev yog ua los ntawm aluminium alloy, nrog rau kev tsim qauv siab thiab tsis tshua muaj suab nrov.

6. Muaj feem xyuam: dav siv nyob rau hauv pej xeem siv machinery, industrial tsheb, tuav machinery, ua liaj ua teb, hav zoov, thiab nuv ntses machinery thiab lwm yam khoom siv.

7. Ob qho kev lag luam thiab kev ntseeg siab tuaj yeem ua tau raws li cov neeg siv khoom xav tau.

Q: Koj puas yog tuam txhab lag luam lossis chaw tsim khoom?

A: Peb yog cov chaw tsim khoom.

Q: Warranty ntev npaum li cas?

A: Ib xyoos warranty.

Q: Koj cov nqe lus them nqi yog dab tsi?

A: 100% ua ntej, tus neeg muag khoom mus sij hawm ntev 30% ua ntej, 70% ua ntej xa khoom.

Q: Yuav ua li cas txog lub sijhawm khoom xa tuaj?

A: Cov khoom lag luam ib txwm siv 5-8 hnub, thiab cov khoom tsis sib xws nyob ntawm tus qauv thiab qhov ntau

Raws li lub chaw tsim khoom muaj peev xwm ntawm ntau hom Hydraulic Pumps, peb tau vam meej thoob plaws lub ntiaj teb thiab peb zoo siab los qhia cov lus pom zoo uas peb tau txais los ntawm cov neeg siv khoom txaus siab thoob plaws ntiaj teb. Peb cov khoom tau txais kev qhuas rau lawv qhov zoo tshaj plaws thiab kev ua haujlwm zoo. Kev tshuaj xyuas zoo ib yam qhia txog kev ntseeg siab thiab kev txaus siab rau cov neeg siv khoom tom qab kev yuav khoom.

Koom nrog peb cov neeg siv khoom thiab paub txog qhov zoo tshaj plaws uas ua rau peb sib nrug. Koj qhov kev ntseeg siab yog peb qhov kev txhawb siab thiab peb tos ntsoov kom tshaj qhov koj xav tau nrog peb cov POOCCA hydraulic twj tso kua mis.