Hauv cov tshuab hluav taws xob hydraulic, radial piston twj thiab axial piston twj yog ob lub thev naus laus zis, ua haujlwm sib txawv ntawm daim ntawv thov nrog lawv cov qauv tsim tshwj xeeb thiab kev ua haujlwm zoo. Txawm hais tias ob leeg paub txog kev hloov pauv ntawm lub zog ntawm lub zog los ntawm kev sib txuas lus ntawm lub piston, muaj qhov sib txawv tseem ceeb hauv lawv cov qauv sab hauv, cov yam ntxwv ua haujlwm thiab cov xwm txheej siv tau.

Cov txheej txheem tseem ceeb sib txawv: "radial" thiab "parallel" kev npaj ntawm pistons

1. Hydraulic radial piston twj tso kua mis: cov pistons yog radially faib

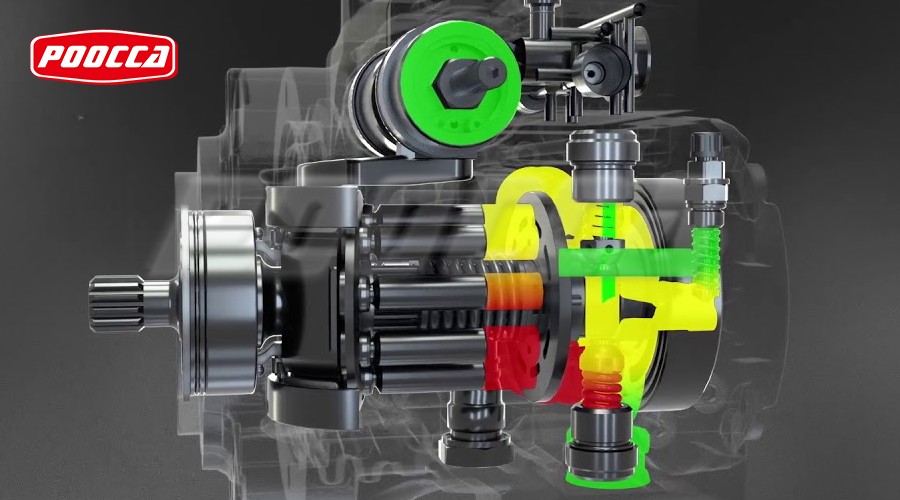

Cov yam ntxwv ntawm tus qauv: Cov pistons tau teem rau hauv lub hnub qub duab raws li radial kev taw qhia ntawm tus tsav ncej (zoo ib yam li lub log spokes), perpendicular mus rau lub ntsiab ncej.

Lub hauv paus ntsiab lus ua haujlwm: Lub piston nyob ze rau ntawm lub nplhaib eccentric cam (Cam Nplhaib) los ntawm kev quab yuam centrifugal lossis lub tshuab thawb. Raws li lub rotor tig, lub piston reciprocates nyob rau hauv lub radial qhov ua kom tiav cov roj suction thiab roj siab txheej txheem.

Cov khoom tseem ceeb: eccentric cam nplhaib, rotor lub tog raj kheej, faib ncej.

2. Hydraulic axial piston twj tso kua mis: lub piston yog teem rau parallel mus rau lub ntsiab ncej

Cov yam ntxwv ntawm tus qauv: Lub piston yog sib npaug rau lub zog tsav thiab sib npaug sib npaug hauv lub tog raj kheej tig.

Lub hauv paus ntsiab lus ua haujlwm: Lub plunger ua tiav cov lus tsa suab los ntawm lub inclination lub kaum sab xis ntawm lub swashplate lossis khoov axis. Qhov loj dua lub swashplate lub kaum sab xis, qhov ntev ntawm lub plunger stroke thiab siab dua qhov tso zis ntws.

Cov khoom tseem ceeb: swashplate / bent axis, rotating lub tog raj kheej, distributor phaj.

Visual sib piv:

Radial twj tso kua mis: Cov qauv yog ntau "robust", haum rau ultra-siab siab, tab sis lub ntim yog loj dua.

Axial twj tso kua mis: Cov qauv yog ntau "compact", haum rau kev kub ceev, kev tswj tsis sib xws, thiab muaj zog ntau dua.

Kev sib piv kev ua haujlwm: siab, efficiency, lub neej thiab suab nrov

1. Lub peev xwm siab

Radial piston twj tso kua mis: Tsim rau ultra-siab siab (tshaj 600-1000 bar), xws li hydraulic presses, cov cuab yeej sib sib zog nqus dej hiav txwv thiab lwm yam kev ua haujlwm hnyav.

Axial piston twj tso kua mis: Lub ntsiab siab ntau yam yog 200-450 bar, thiab qee cov qauv high-end tuaj yeem ncav cuag 600 bar, haum rau kev siv tshuab, txhaj tshuaj molding tshuab, thiab lwm yam.

Xaus: Yog tias qhov kev xav tau siab tshaj 500 bar, lub twj tso kua mis radial yog qhov kev xaiv nkaus xwb; yog tias nws qis dua 400 bar, lub twj tso kua mis axial yog tus nqi ntau dua.

2. Flow stability thiab suab nrov

Radial twj tso kua mis: tsawg dua plungers (feem ntau yog 5-7), loj ntws pulsation, suab nrov (ntau tshaj 80 dB).

Axial twj tso kua mis: ntau plungers (7-9 los yog ntau tshaj), smoother flow output, qis suab nrov (70-75 dB).

Daim ntawv thov cuam tshuam: Axial twj yog nyiam rau cov suab nrov-sensitive scenarios (xws li cov cuab yeej kho mob thiab cov cuab yeej siv tshuab precision).

3. Kev ua tau zoo thiab kev tswj hwm qhov sib txawv

Radial twj tso kua mis:

Kev siv tshuab ua haujlwm siab (92% +), tab sis kev hloov pauv tsis yooj yim, cam eccentricity hloov, teb qeeb.

Haum rau kev hloov pauv ruaj khov lossis qis-ceev thiab siab-siab.

Axial twj:

High volumetric efficiency (95% +), hloov pauv hloov pauv tswj (los ntawm kev kho lub kaum sab xis ntawm lub phaj swash), thiab cov lus teb ceev ceev.

Haum rau kev tswj hwm qhov sib txawv ntawm qhov ceev thiab lub zog txuag hluav taws xob (xws li excavators thiab cua zog sib txawv pitch systems).

4. Lub neej thiab kev saib xyuas

Radial twj tso kua mis: qauv yooj yim, muaj zog muaj kuab paug tsis kam, haum rau hnyav ib puag ncig (xws li mining machinery).

Axial twj tso kua mis: Lub phaj swash thiab plunger khub muaj qhov yuav tsum tau ua rau cov roj huv huv thiab xav tau kev pom zoo (NAS 1638 Chav Kawm 6 lossis siab dua).

Kev sib piv ntawm cov xwm txheej ntawm daim ntawv thov

1. Lub ntsiab sib ntaus sib tua ntawm radial piston twj

Ultra-siab siab hydraulic system:

Hlau sib sau (hydraulic xovxwm, forging xovxwm)

Cov khoom siv dej hiav txwv tob (ROV hydraulic zog)

Tub rog kev lag luam (submarine hydraulic system)

Ib puag ncig huab cua:

Mining machinery (kev ua qias tuaj, cuam tshuam tsis kam)

Roj Drilling (High-pressure av nkos twj tso kua mis)

2. Qhov tseem ceeb ntawm axial piston twj tso kua mis

Mobile hydraulic khoom:

Kev tsim kho tshuab (excavator, loader)

Agricultural machinery (combine harvester)

Industrial automation:

Txhaj tshuaj molding tshuab, tuag-casting tshuab

Cua zog variable pitch system

Aerospace:

Aircraft tsaws iav hydraulic system

Kev lag luam tiam sis thiab cov lus qhia kev txhim kho yav tom ntej

1. Kev ua kom zoo ntawm cov twj axial

Kev siab dua: Qee cov tuam txhab lag luam (xws li Bosch Rexroth thiab Parker Hannifin) tau tsim 600 bar axial twj los tawm tsam qhov zoo ntawm cov twj radial.

Kev txawj ntse tswj: kev sib xyaw sensors kom ua tiav lub sijhawm hloov pauv ntawm kev ntws thiab siab (IoT hydraulic system).

2. Irreplaceability ntawm radial twj

Lub 1000 bar + kev ua lag luam tseem yog cov twj siv hluav taws xob, xws li ultra-siab siab txiav dej thiab cov cuab yeej tshwj xeeb metallurgical.

Cov khoom siv tau zoo: ceramic plungers thiab carbon fiber reinforced plhaub ua rau lub neej.

3. Kev tiv thaiv ib puag ncig thiab kev siv hluav taws xob xav tau tsav kev tsim kho tshiab

Axial twj muaj ntau dua nyob rau hauv txoj kab nrog lub zog txuag kev xav tau nyob rau hauv "dual carbon" lub hom phiaj vim lawv cov yam ntxwv sib txawv ntawm qhov ua tau zoo.

Radial twj tau pom cov ntsiab lus loj hlob tshiab hauv lub zog tauj dua tshiab (xws li tidal power generation hydraulic systems).

Radial piston twj thiab axial piston twj sawv cev rau ob txoj kev xav ntawm hydraulic technology:

Radial twj yog "cov neeg ua haujlwm fais fab" tsim rau ultra-siab siab thiab muaj kev ntseeg siab;

Axial twj yog "tag nrho cov neeg ua si" nrog kev ua haujlwm zoo dua, tswj tau thiab compactness.

Yog tias koj muaj kev xav tau, thov hu rau poocca hydraulic chaw tsim tshuaj paus.

Post lub sij hawm: Jun-10-2025